Listen to our podcast 🎧

.png)

Introduction

Across the globe, major manufacturers such as Philips, Nike, and Adidas have incurred losses reaching millions or even billions due to supplier disruptions. Such incidents reveal how a lack of proactive supplier security and monitoring can bring entire manufacturing operations to a halt.

Many organizations focus their continuity planning on large-scale crises such as natural disasters or geopolitical conflicts. The most frequent disruptions arise from everyday challenges, including production delays, quality lapses, or transport problems.

Despite modernizing supply chain operations with automated technologies, gaps remain in real-time performance monitoring and early-warning capabilities.

This post outlines practical AI security strategies that enable Chief Operating Officers (COOs) to enhance supplier continuity, reduce operational risk, and make informed decisions faster.

Why Investing in AI is Key to Business Continuity in Manufacturing ?

Supplier disruptions can cost companies an average of $184 million per year, with major supply chain incidents rising 38% in 2024. Traditional monitoring methods often detect issues too late, after production is already impacted.

AI transforms how supply chain risks are managed:

- Early warning detection: AI continuously monitors supplier data to flag potential delays, capacity shortages, or quality deviations before they escalate.

- Prioritized risk focus: Leaders can identify high-risk suppliers, assess potential operational impact, and allocate mitigation resources efficiently.

- Data-driven decisions: COOs base actions on real-time insights rather than assumptions, reducing uncertainty and operational guesswork.

- Enhanced accountability: AI provides transparency across multiple suppliers, showing trends in performance, compliance, and reliability.

By investing in AI, manufacturers gain the ability to anticipate disruptions, secure alternative suppliers quickly, adjust production schedules, and protect revenue streams.

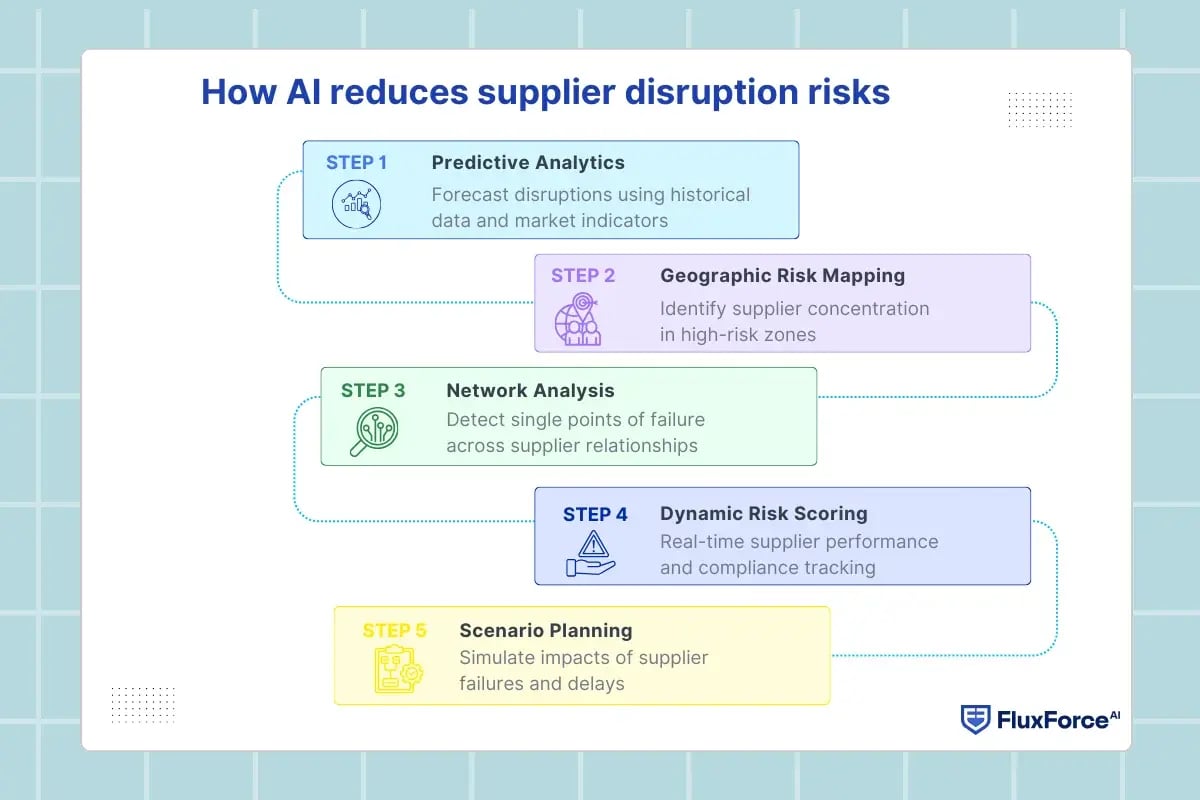

How AI reduces supplier disruption risks ?

AI supports resilient supply chain management by analysing multiple risk factors simultaneously and providing actionable insights across supplier tiers. Key capabilities include:

AI supports resilient supply chain management by analysing multiple risk factors simultaneously and providing actionable insights across supplier tiers. Key capabilities include:

1. Forecasting and Predictive Analytics

AI leverages historical data, real-time supplier updates, and external market indicators to forecast potential disruptions. Predictive failure analysis identifies early warning signs such as capacity limitations, delayed shipments, or process bottlenecks. Forecasting enables COOs to plan alternative sourcing, adjust production schedules, and maintain business continuity under uncertain conditions.

2. Geographic and Environmental Risk Mapping

Certain suppliers operate in regions prone to natural disasters, political instability, or transport bottlenecks. AI maps geographic risk exposure, highlighting supplier concentration in high-risk zones. This analysis supports building a resilient supply chain by identifying opportunities for supplier diversification, inventory buffers, or relocation of critical operations.

3. Network Dependency Analysis

AI evaluates supplier relationships across multiple product lines and identifies single points of failure. Suppliers providing unique components or serving multiple production lines pose a high operational risk. Recommendations generated by AI include alternative suppliers, backup inventory allocations, and network reconfiguration to enhance resilience.

4. Dynamic Risk Scoring

AI continuously evaluates supplier performance, quality metrics, delivery timeliness, financial health, and regulatory compliance. Risk scores adjust in real-time according to internal data and external market conditions. COOs gain precise insights into which suppliers pose emerging threats and can prioritize interventions efficiently.

5. Automated Scenario Planning

AI enables scenario modelling for supplier failures. Simulation of production stoppages, shipment delays, or supplier insolvency estimates operational, financial, and contractual impacts. Scenario analysis supports contingency planning, ensuring supply chain continuity using artificial intelligence.

Integration of AI into existing supply chain management systems

Most manufacturers already use ERP and procurement platforms to track inventory and manage orders. Integrating AI may seem complex, but modern tools connect seamlessly with existing infrastructure.

API-Based Connectivity

AI platforms can pull data from ERP systems and push alerts to dashboards automatically. Integration typically requires minimal IT effort and can be completed within weeks.

Cloud-Based Deployment

Cloud AI services eliminate hardware requirements and allow access through web browsers. Automatic updates and on-demand scaling make deployment faster and cost-effective, even for mid-sized manufacturers.

Minimal Training Requirements

Modern AI tools, those built by FluxForce AI, have intuitive interfaces and pre-built templates. Teams adapt quickly without extensive technical expertise, allowing procurement and operations staff to focus on actionable insights rather than software mechanics.

Real-Time Processing

Unlike traditional batch systems, AI analyzes transactions as they happen, updating risk scores and sending alerts immediately. This speed enables faster decision-making and more proactive supplier management.

The extended role of AI in Supplier Security and Compliance

AI’s role in supplier management now extends beyond monitoring networks. It actively identifies risks, enforces compliance, and helps COOs maintain uninterrupted operations while ensuring suppliers meet regulatory standards.

Enhanced Cybersecurity Monitoring

AI constantly evaluates supplier systems to identify unusual activity or potential breaches. By flagging issues in real time, it prevents disruptions that could halt production or compromise sensitive data.

Proactive Threat Detection Across Supplier Networks

Rather than reacting to incidents, AI predicts vulnerabilities in supplier networks, including outdated systems, misconfigurations, or access gaps, enabling companies to fix problems before they escalate.

Automated Security Audits

AI conducts continuous audits of supplier security protocols, verifying encryption, data-handling practices, and policy adherence. This reduces the need for manual reviews and ensures consistent standards across all partners.

Dynamic Compliance Management

AI keeps track of evolving regulations, certifications, and audit requirements across regions. By automatically maintaining records and highlighting compliance gaps, it safeguards businesses against penalties and reputational risk.

Strengthening Operational Resilience

Integrating AI for both security and compliance ensures suppliers remain reliable, operational continuity is maintained, and COOs can make data-driven decisions to mitigate risks proactively.

Complexities of AI-powered supplier risk assessment

AI can transform supplier risk management, but several factors affect its effectiveness:

- Incomplete or Inaccurate Supplier Data: AI models require timely, accurate data from all supplier tiers. Missing production metrics, delayed shipment updates, or inconsistent reporting can reduce prediction reliability.

- Limited Visibility Across Supplier Tiers: Most disruptions start with tier-two or tier-three suppliers. Without data from these tiers, AI cannot provide a complete view of potential risks.

- Rapidly Changing Market and Operational Conditions: Supplier performance, financial health, and external factors such as weather, geopolitical events, or material shortages can change quickly. AI models must adjust in real-time to remain relevant.

- Integration of AI Insights into Decision-Making: AI provides risk scores and forecasts, but actionable decisions require operational context. COOs must ensure procurement, operations, and risk management teams align with AI outputs for effective response.

- Supplier Collaboration: Accurate predictions depend on supplier participation. Suppliers must share production, financial, and quality information consistently to enable AI to identify early warning signs.

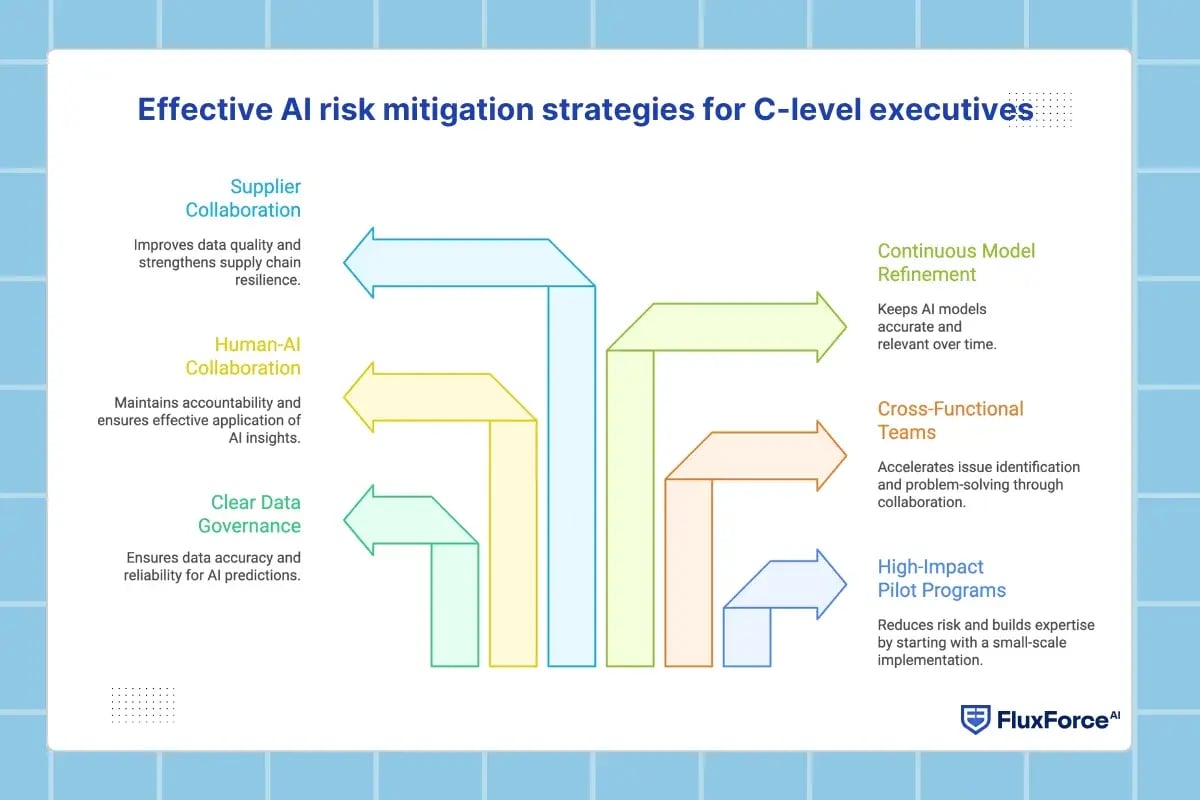

Effective AI risk mitigation strategies for C-level Executives

COOs in 2025 need strategic approaches to implement AI successfully in supply chains. Proper planning ensures AI effectively supports business continuity and strengthens supply chain resilience. The following strategies outline practical implementation steps:

#1 Start with High-Impact Pilot Programs

Full-scale AI deployment carries significant operational risk. Begin with one critical supplier category. Implement AI monitoring for this group first. Measure outcomes, record improvements, and calculate ROI. Gradual rollout limits investment, builds internal expertise, and demonstrates value before broader deployment.

#2 Establish Clear Data Governance Policies

AI systems require accurate, consistent data to generate reliable predictions. Define collection standards, update frequency, and quality requirements. Assign clear ownership for each data type. Implement validation checks and regular audits. Strong governance ensures outputs are actionable and trustworthy.

#3 Create Cross-Functional Implementation Teams

AI adoption impacts multiple departments simultaneously. Procurement, IT, operations, and finance must collaborate closely. Form teams with clear goals and decision-making authority. Remove organizational barriers. Cross-functional collaboration accelerates issue identification, problem-solving, and ensures AI supports operational continuity.

#4 Develop Human-AI Collaboration Protocols

AI provides recommendations, while executives retain final decision authority. Specify tasks AI executes autonomously versus those requiring review. Establish clear escalation procedures. Document responsibilities. Proper protocols maintain accountability and ensure AI insights are applied effectively across supply chains.

#5 Invest in Continuous Model Refinement

AI models must evolve with changing supplier behaviours and market conditions. Conduct regular reviews and compare predictions with real outcomes. Retrain models with updated data. Update algorithms as needed. Continuous refinement maintains accuracy, relevance, and long-term predictive value.

#6 Build Supplier Collaboration Frameworks

AI effectiveness depends on supplier transparency and data sharing. Suppliers must understand the monitoring purposes and share accurate information. Communicate plans clearly, explain benefits, and establish formal agreements. Strong collaboration improves data quality, accelerates issue resolution, and strengthens supply chain resilience.

Conclusion

Supplier disruptions are a major risk for manufacturing operations, threatening production continuity and revenue. However, strategically integrating AI provides Chief Operating Officers (COOs) with real-time visibility across all supplier tiers and their activities.

With seamless connectivity to ERP and procurement systems, advanced AI models ensure timely data flow, automate alerts, and equip COOs with actionable insights for proactive risk mitigation.

Share this article